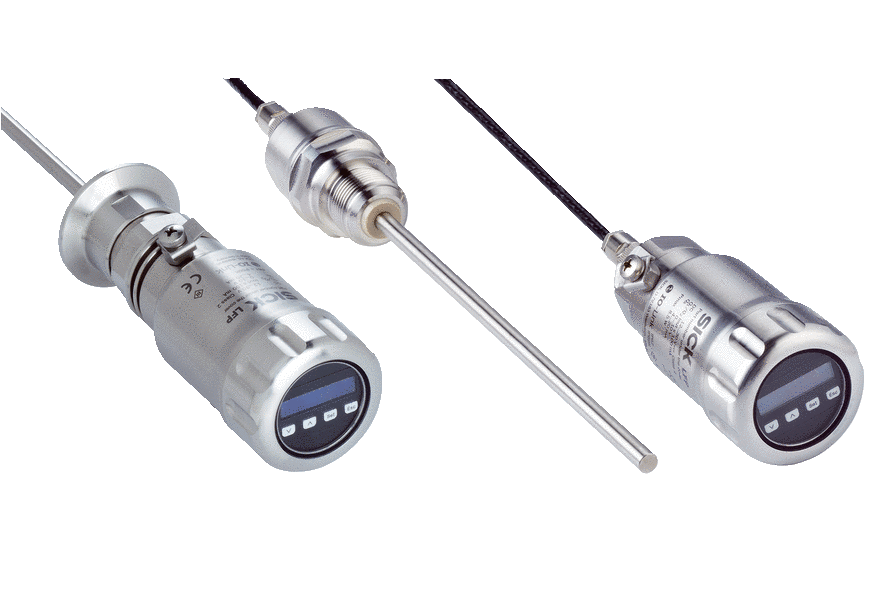

SICK – LFP Inox Sensor

The LFP Inox is a hygienic level sensor for liquids using TDR technology – a process for determining the time of flight of electromagnetic waves. The time difference between the sent pulse and the reflected pulse is used to generate a level signal, both as a continuous value (analog output) and a freely positional switching point (switching output). Its modular connection system allows simple and flexible installation in any application.

Description

The LFP Inox is a hygienic level sensor for liquids using TDR technology – a process for determining the time of flight of electromagnetic waves. The time difference between the sent pulse and the reflected pulse is used to generate a level signal, both as a continuous value (analog output) and a freely positional switching point (switching output). Its modular connection system allows simple and flexible installation in any application.

- Level measurement in hygienic applications

- Rod probe can be cut to length manually up to 4,000 mm long with Ra ≤ 0.8 µm

- Process temperature up to 180 °C, process pressure up to 16 bar

- CIP/SIP-resistant

- High enclosure rating: IP 67 and IP 69, autoclavable

- Interchangeable hygienic process connections

- 3 in 1: combines display, analog output, and binary output

- Remote amplifier with process connection

- IO-Link 1.1

- Rugged design increases service life

- High flexibility – rod probe can be cut to length and connection concept is interchangeable.

- Cost savings because of multiple output signals: one system for both point level and continuous level measurement

- Maintenance-free and easy to commission without calibration, saving time and money.

- Remote display of measured values and saves space

APPLICATIONS

• Level monitoring in buffer tanks of filling systems and filling machines

• Level monitoring in rinsing systems

• Level monitoring in CIP systems

• Level measurement in mixing systems in the cosmetics and pharmaceuticals industry

• Level monitoring in industrial processes with difficult ambient conditions